Screw Piling Foundations

Screw Pile Foundation

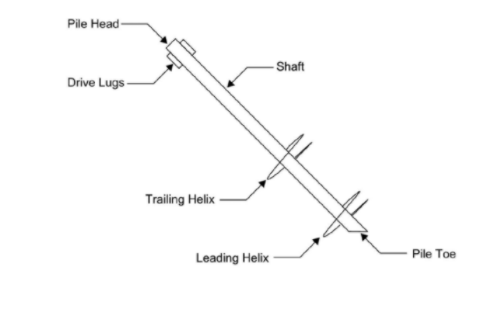

The history of screw piles can be traced back to the 1800s as a simple yet effective means for construction of structures of the times. Screw piles are a type of piled foundation, or retaining wall anchor. They are made of circular hollow steel sections with one or more helices welded to the shaft that provide a self-tapping mechanism during installation. As with all great technologies, screw pile foundations have now been implemented in wide variety of structures throughout the world.

Choosing the foundation for a home is an extremely important decision. The entire building depends on a stable and solid foundation. Until a few years ago, there wasn’t a large selection of materials and equipment to service foundations. But with the advancement in civil technologies a rock-solid foundation can be laid in just a couple of days. One of the most environmentally sustainable, cost effective and fastest ways to establish a base for a building of varying sizes is screw pile foundations. In this article, we will consider in detail all the features of this structure.

The main implementation is screw piles being used

- residential and commercial foundation works,

- earth reinforcement anchors

- pipelines and conveyor systems

- lightweight and entertainment structures

- temporary building and shade structures

Screw piles foundations can be used to support structures transferring loads through weak soils to harder soils or rock, and in tension to resist uplift loads from structures and provide support to retaining structures. In most situations the installed screw pile will have both compression and tension loads.

Screw piles foundation transfer loads evenly through the shaft and spread out from the helix.

Each project is specific. To achieve the most cost-efficient design, our engineers will design a shaft and helix system of the perfect size and thickness to handle the design load catered to the geotechnical condition of the work zone.

Application of on Screw Piles Foundation:

The pile-screw foundation is undemanding to soil characteristics and landscape features. It is ideal for terrain installations where dense bearing soil layers are well below the surface mark.

Ground conditions where screw piling shine:

– Slopes;

– Heavily watered soils;

– Peat soils;

– Areas constantly flooded with floods;

– Heaving soils;

– Moving and floating soils.

Screw Piles foundations are built even near the location of various infrastructure communications and near trees with dense root systems, since they are not an obstacle to their installation.

Dimensions and load

Screw pile safe working load

| Safe working load | |

| Description | Australian standard |

| Piling design and installation | AS2159 |

| Structural steel hollow sections | AS1163 |

| Steel grade | AS4100 (C350OLO) |

| Galvanising | AS/NZS 2312 |

| Welding | AS 1554 |

| Standard Characteristic | |

| CHS diameter | 76mm |

| Helix diameter | 300mm |

| CHS length | 2m, 3m or 4m |

| CHS thickness | 5mm |

| Helix thickness | 10mm |

| Extensions | available according to project specifications |

| Safe working loads (subject to soil density) | 90kn |

| Piledrive products are designed to bear compressive, tension and lateral loads through the blade at the bottom of the shaft. | |

| The monitoring of the applied torque on site allows for the confirmation of the allowable bearing capacity of the soil. | |

| Standard Characteristic | |

| CHS diameter | 88.9mm |

| helix diameter | 350mm |

| CHS length | 3m, 4m |

| CHS thickness | 5.5mm |

| helix thickness | 12mm |

| extensions | available according to project specifications |

| safe working loads subject to soil density | 140kn |

| Piledrive products are designed to bear compressive, tension and lateral loads through the blade at the bottom of the shaft. | |

| The monitoring of the applied torque on site allows for the confirmation of the allowable bearing capacity of the soil. | |

| Standard Characteristic | |

| CHS diameter | 114mm |

| helix diameter | 450mm |

| CHS length | 2m, 3m, 4m |

| CHS thickness | 6mm |

| helix thickness | 12mm |

| extensions | available according to project specifications |

| safe working loads subject to soil density | 190kn |

| Piledrive products are designed to bear compressive, tension and lateral loads through the blade at the bottom of the shaft. | |

| The monitoring of the applied torque on site allows for the confirmation of the allowable bearing capacity of the soil. | |

| Standard Characteristic | |

| CHS diameter | 168mm |

| helix diameter | 600mm |

| CHS length | 3m, 4m, 6m |

| CHS thickness | 6mm |

| helix thickness | 12mm |

| extensions | available according to project specifications |

| safe working loads subject to soil density | 280kn |

| Piledrive products are designed to bear compressive, tension and lateral loads through the blade at the bottom of the shaft. | |

| The monitoring of the applied torque on site allows for the confirmation of the allowable bearing capacity of the soil. | |

Extension of Piles

The design of the piles provides for the possibility of their extension, since the standard length is not always sufficient to ensure the required level. This is especially true when building houses on slopes, where the height differences can significantly exceed 2.5 m. The build-up is carried out by welding – 2 piles are joined together with a preliminary fitting of a piece of pipe with a slightly larger diameter, which is subsequently welded to the lower and upper support.

The upper part of the pile after pouring with concrete, as a rule, is covered with a steel head or “heel” in the common people, which is also welded to a metal pipe.

The service life of screw piles

The warranty service life of foundation piles for a house, which is provided by most contractors, is usually a minimum 50 years.

The actual service life can be much longer – it all depends on the operating conditions and the characteristics of the anti-corrosion compound used to protect them.

BEARING CAPACITY OF SCREW PILE FOUNDATION DEPENDS ON:

- Type and properties of the soil

- Surface and/or groundwater conditions

- Geometry of the pile (pipe size, helix size, number of helixes, material thickness)

- Pile material (new steel only)

- Size of pile (cross-section, length)

- Embedment depth of pile

- Position of pile (vertical, horizontal or battered)

- Spacing between piles (interaction of piles, group efect)

- Installation torque

- Type of loading (alternating, step-loading, static and others)

Screw piles are a more cost effective and cost saving option to bored piers. You are less prone to environmental factors and the workload is typically 10 times quicker.

Advantage of screw piles foundation

- Can be installed in all clients, weather or ground conditions

- No excavation usually required

- No downtime, build as soon all the piers are down

- Environmentally friendly

- the most reliable and economical solution available

- Minimal to No vibration when screwing in – the absence of vibration feedback when screwing the blade support makes the process safe for nearby buildings.

The Best Screw Pile Foundation Contractor in Melbourne and Victoria Region

Pile Drive reinforced Screw piles that are ideal for each specific object. Here you are provided with the best quality piles. We provide the complete package. This includes the design, manufacture, supply and installation of screw piles to cater to your site. We have catered to some of the largest screw piling contractors in Melbourne. No job is too small or too big. We look forward to hearing from you on your next project.

FREE QUOTE

Contact us today for a free quote.

ENQUIRIES

sales@piledrive.com.au

CONTACT US

0430 045 313

OFFICE HOURS